By Julia Redman, Lecturer at the London College of Fashion, University of the Arts London, and Founder/Owner of Responsible Buying and Sourcing Consultancy, Buyers Eye.

A couple of weeks ago I visited Leicester Made, a trade fair focused on the regeneration of UK apparel manufacturing in and around Leicester. What I discovered was an incredible coming together of like-minded people and businesses, highly dedicated to changing the British fashion industry and the way it operates to deliver future prosperity for all its stakeholders.

At a time when fashion faces intense scrutiny over its environmental impact, sourcing ethics, and economic viability, the show delivered a sharp, clear message: the industry cannot afford business as usual. Across panels packed with leading voices – from suppliers and sustainability advocates to technologists and buyers – three themes were evident: technology, transparency, and transformation.

Panel Debate: Unlocking Innovation in the Apparel Industry – Exploring AI, digital innovation & automation in apparel production.

Panellists: Mar Fernandez, Alvanon, Market Development Consultant Director, Naeem Riaz, Founder at Loop Kinetics Ltd, Co-Founder at Maeknit Inc (US), Maggie Chen, Style3D | ASSYST, Partner, Louise Laing, Phygital Twin, Founder, Danny Gazit, Kornit Digital, Chief Product Officer

The session began with a technical deep dive into product development, with host Simon Platts highlighting the staggering costs behind fashion sampling. A sample can cost up to 25 times its FOB (freight on board) price, he noted, a cost that inevitably makes its way into the final product price. However, the panel was quick to shift focus from cost alone to opportunity.

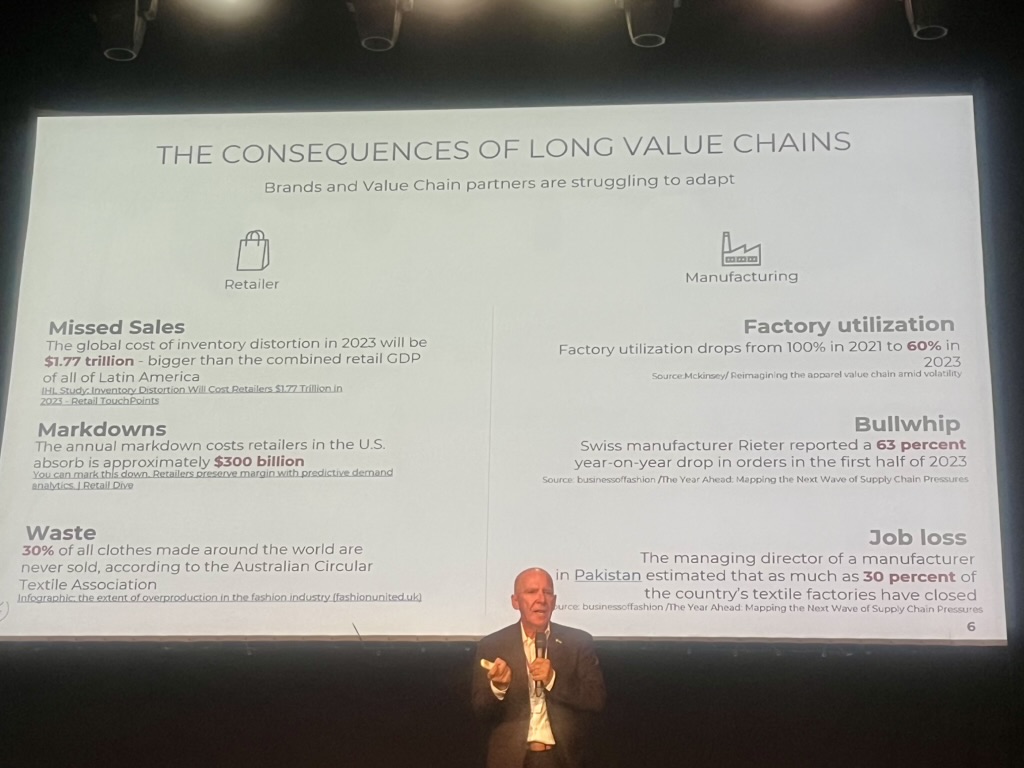

Virtual sampling, powered by 3D tools and digital mannequins from companies like Alvanon, is revolutionizing the early stages of design. As Naeem explained, “get the fabric right, and virtual sampling becomes not just viable – but vital.” These tools eliminate guesswork, reduce waste, and accelerate decision-making. It’s a vision of design where technology allows brands to “design it, sell it, then make it,” rather than producing in bulk and discounting what doesn’t sell – a model that currently leads to 30% of potential profit lost through markdowns, overstock, and waste, as Danny also emphasised.

The trend toward increased styles with reduced volumes makes traditional sampling even more expensive per unit. As Maggie pointed out, “the sample-to-order ratio is getting lower, so the cost of sampling per order goes up.” Virtual sampling, therefore, becomes an essential counterbalance, a recurring theme across discussions.

AI also made its presence felt. Naeem described how fashion businesses are leveraging data mining to better understand buyer preferences and anticipate demand—paving the way for more targeted, efficient production.

Panel Debate: Reimagining Fashion Through Sustainable Change – focusing on designing with purpose, producing with less & planning for a better tomorrow.

Panellists: Simon Platts, SP &KO Limited, Co-Founder, Paul Kerssens, United Repair Centre, COO, Salli Deighton, LaundRE, Founder, Alex Simpson, Universal Music Group, Product Development Manager, Chris Desai, UOCEAN, CEO

By 1:15pm, the conversation turned from innovation to introspection. Chris reframed the fashion crisis as fundamentally a human crisis, not just one of waste or climate. “We need a wholesale change of mindset,” he argued, urging for widespread customer education and cultural shift.

Paul added that long-term value should be built through repair systems and service-led models – approaches that don’t just reduce waste, but enhance customer satisfaction and brand loyalty. The business case for change, he said, is already here.

Jenny and Sally spoke to a critical but often overlooked issue: the knowledge gap among buyers. Without walking factory floors or understanding wash processes, many buyers lack the expertise to cost garments properly or develop lasting supplier relationships. This creates a race to the bottom on price, rather than building value through shared goals.

As a Head of Buying, on more than one occasion, I hired a minibus and took a trip to Leicester with all the junior members of my buying team, so that they could visit suppliers, learn & understand the processes and techniques involved in knitting, weaving, printing, manufacturing, cost breakdown and the importance of people and communication in our supply chains. This would not have been possible without the support & effort of Leicester businesses, whose teams gave up their time and extensive knowledge! I will always be grateful for the help you gave these budding buyers at the beginning of their careers.

Legislation came up again and again. Chris was blunt: “I don’t think humanity can be trusted to do the right thing.” Catherine added that just as legislation changed consumer behavior around carrier bags, it could steer fashion toward better practices. A level playing field, enforced by law, could make ethical and sustainable practices a norm rather than a niche.

The panel also argued for embedding fashion creation and care into school curricula, building a generation that understands not just how to consume fashion – but how to create and care for it responsibly.

Onshoring Keynote – Bill McRaith

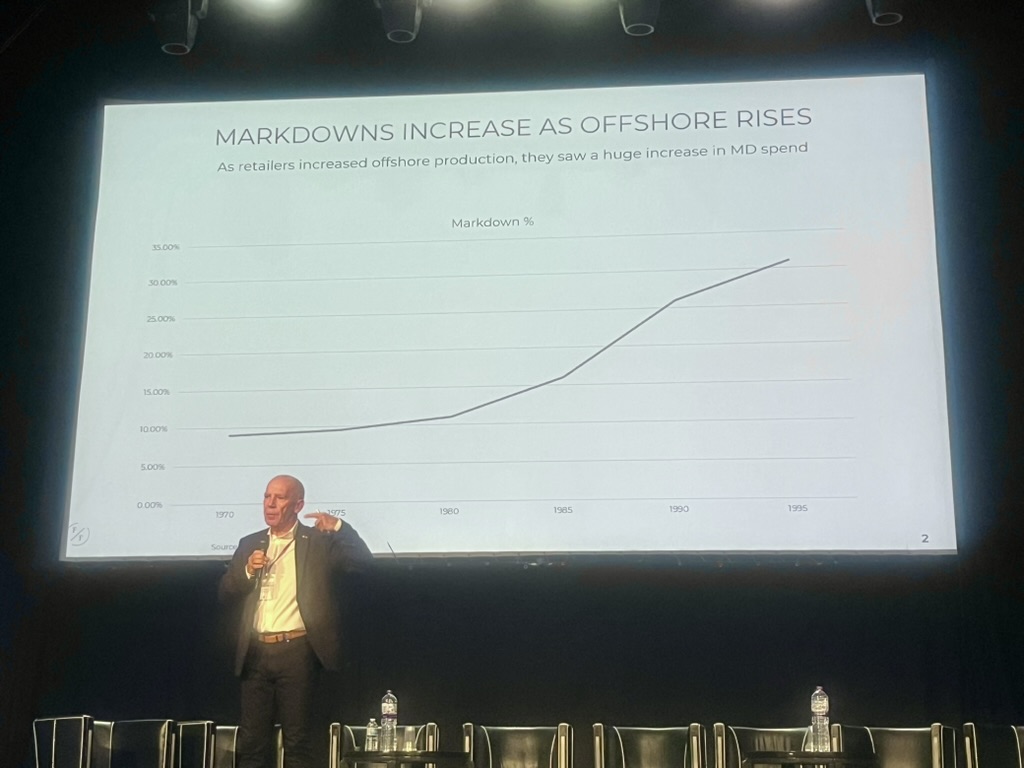

This man talks my language! Bill explained how from the 70’s/80’s as product moved offshore, markdowns increased, under the ever increasing pressure to drive volume and intake margin. I can relate to this; when I started my career at BHS in the 1990’s, I was buying from several factories in Leicester (William Bancroft), Nottingham (Clifton Styles) and Stranraer (Pasolds), but as my career progressed, the brands and retailers I worked for bought less and less from these UK sources, and many of these facilities themselves moved their production off shore in order to compete.

Bill also shared a great many thought provoking soundbites that signpost the fundamental issues we are facing as an industry and how we, as fashion businesses need to adapt/evolve to survive!

- Growth is not happening in UK – it is coming from emerging markets eg India

- Legislation needs to stop Shein & Temu, their sales are increasing vs everyone else stagnating. Both are now on shoring & nearshoring faster than any other business.

- Shift away from a victim mindset, change the model, become agile to deliver change/success/profitability.

- Shrink/shorten the value chain. We are still buying too much that by the time it is delivered, the customer no longer wants.

- Operating costs are where we are losing money (incl. markdown), whilst we try & squeeze pennies out of the manufacturing cost by buying cheaper & cheaper, further & further off shore.

- Fashion businesses are also losing full price margin because they are out of stock of key bestsellers/trends and cannot get more because of their extended supply chains.

- You got the cheapest price, great intake margin! However, end of season profitability is poor due to off shore focus/high volume/high markdown/low full price sell thru.

- Balance off-shore, near-shore, on-shore – minimise the sales & profit risk – create a matrix operation. Collaborate with a partner that can help you mitigate risk with near shore/on shore capability.

- Partner off shore factories with near shore equivalents.

- As a supplier this is a reason for brands and retailers to work with you – offer matrix supply with opportunities to trial on-shore/near-shore & place volume off-shore.

- Equally, buy volume off shore & repeat on-shore/near-shore.

- Reduced waste/over ordering leads to lower water impact, carbon emissions etc.

- Help brands & retailers reduce their operations costs by being more reactive.

- KPI’s & remuneration of buyers/merchants/supply chain tied to profit. If you sort out operations costs/profitability, sustainability & carbon targets will follow.

- UK garment manufacturing has the potential to reach parts of the community, and employ people eg. parents of young children, on shifts that work around them – bring some of the 9M unemployed back into UK manufacturing jobs.

- Collaboration across retail on common fabric supply chains?

- There is a common misconception that all the innovation is happening off shore. Is it? Or is that just where the investment in innovation is happening?

Panel Debate: Why Onshoring Works for People, Planet and Profit – discussing the financial, environmental and logistical advantages of reshoring production.

Panellists: Bill McRaith, Future-Proof Fashion, Executive Advisor, Jake Hall, By Jake Hall, Founder & Creative Director, Kate Hills, Make it British, Consultant, Nick Beighton, Ex CEO ASOS, EX CEO Matches Fashion, Chairman Secret Sales, Ecommerce/Digital Business Builder, Fiona Lambert, The Twenty Club, President and Author, Caren Downie, Yaw Studio, Founder and Director

The 2:45pm session brought a practical lens to nearshoring, reshoring, and the economics of local production. Nick, who helped establish ASOS’s Leicester sourcing base, emphasised that proximity sourcing now makes up 4% of their £1.5 billion turnover. The old sourcing model – wide and deep—is “running out of steam.”

Caren, of Finery explained that a third of their production was based at Fashion Enter in the UK, stressing that putting product first doesn’t mean sacrificing price but rather elevating quality and reducing waste. Jenny noted that real change requires C-suite commitment – not just words but investment.

Jake Hall captured the creative urgency: if you can’t quickly action trends like deconstructed tailoring, you’re out of the game. Kate emphasized that factories need consistency, not “big businesses chasing price.” Strong supplier relationships aren’t built on cost-cutting alone—they need trust and loyalty.

Bill Mcraith delivered a sobering yet strategic perspective. “Profit. People. Planet. In that order,” he stated, calling for a shortened value chain to combat markdown losses, overproduction, and missed reorders. He urged retailers to balance offshore, nearshore, and onshore operations to mitigate sales risk, reduce environmental impact, and regain profitability.

He also challenged a deeply ingrained mindset: chasing the lowest offshore price doesn’t guarantee profitability. The real money is lost in operating costs and markdowns, not raw manufacturing savings. “Cheap clothes aren’t cheap,” echoed Nick – someone is paying, whether it’s the environment, the worker, or the business itself.

Final Thoughts: A Call for Collective Action

Several speakers, including Fiona and Kate, pointed to the urgent need for storytelling and rebranding in the sector – from the factory floor to the policy table. There’s a disconnect between public perception and the gritty, skilled, and deeply human work that underpins the industry. “This is a business about people,” Kate reminded us.

So where is the industry voice? That question, asked more than once during the day, hangs in the air. What is clear is that no single silver bullet – not AI, not legislation, not proximity sourcing – will solve fashion’s systemic problems. But collaboration might.

Whether through co-operative models, matrix supply chains, or integrated educational efforts, the path forward is one that ties profitability to responsibility. With UK manufacturing poised to offer flexible employment, reduced lead times, and lower carbon emissions, the moment to act – and invest, is now.

As the trade fair closed, there was one prevailing sentiment: now is the moment. And perhaps, just perhaps, the industry is finally ready to seize it.

Exhibitors & Participants: this is not an exhaustive list, just a few that are really pushing the boundaries!

LaundRE “the UK’s first circular denim hub” https://www.laundre.co.uk/

The Fashion Guild “digital fashion & AI services & support” https://www.thefashionguild.com/

Phygital Twin “bringing digital fashion to life” https://phygitaltwin.io/

Ameba “cutting the wasted time, money and product in your supply chain” https://www.ameba.ai/

Make it British “Make it yours, make it local, make it British” https://makeitbritish.co.uk/

Meesha Group “enabling brands to move at the speed of culture” https://meeshagroup.co.uk/

Loop Kinetics “giving your apparel venture a head start” https://www.loopkinetics.com/

Sponsors:

Fashion Enter London based product development & production https://fashion-enter.com/

Kornit Digital Print on Demand Technology https://www.kornit.com/

Alvanon Sizing Intelligence Ecosystem https://alvanon.com/

ASBCI Bringing together businesses from across the fashion & textile supply chain https://www.asbci.co.uk/

Style 3D Reduce waste, boost efficiency, streamline decisions https://www.style3d.com/

⸻

For more insights please like and follow “A Buyer’s Life” on wordpress or visit my website https://www.buyerseye.co.uk/